By Simon Petree, Green Leaf Forest Products

February 19, 2020

When you’re operating a small business it doesn’t take long to realize the difference between just getting by and making a profit comes from paying attention to the “little things.” Over the past fifteen years I’ve found that some things I never even thought about when I started my portable thin-kerf sawmilling business have popped up and played an important role in allowing me to survive and then grow my business.

One of those “little things” is something I once spent thousands of dollars per year on - sharpening bandsaw blades. Today, thanks to some truly revolutionary technology Wood-Mizer offers, I’m saving about $300 or more per month by sharpening my own blades. When you’re looking to be profitable, $300 per month can be a big deal!

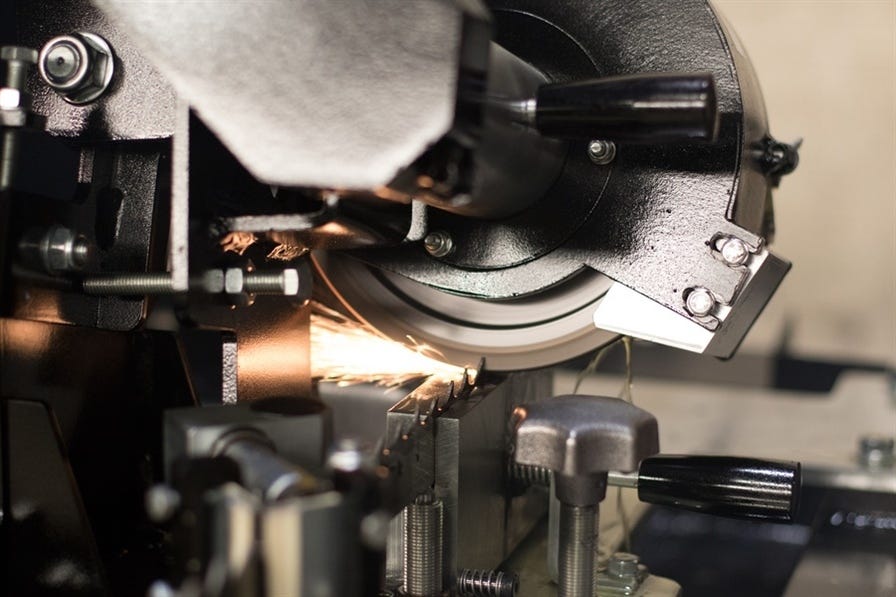

Anyone who’s sharpened blades for very long remembers that, until a few years ago, blade setting and sharpening was a laborious and time consuming job with results not always being as consistent as might be hoped for. The revolution, at least in my world of portable band sawmilling, was the introduction of Wood-Mizer’s CBN (Cubic Boron Nitride) grinding wheel and the blade sharpeners and setters to make use of it. CBN is one of the hardest materials known to man, second only to diamonds. Used on a grinding wheel it far outperforms the technology we used to have available for sharpening blades; it lasts longer than old wheels did and, more important to me, it keeps its shape for the life of the wheel. No more having to constantly dress the grinding wheel to the profile of the individual blade every time you want to sharpen a blade.

At a minimum, sharpening a sawmill blade today using a CBN wheel is 50% faster than the same job in the old days and the simplicity of the modern machinery makes it an easy job to learn. Those of us who did our own sharpening years ago usually had to do the job ourselves because it was complicated. Now, I know several fellow sawmill owners who have their kids or employees do the sharpening. A sawyer can now spend more time sawing and less time on the blade sharpening and that means more time to be making money when the money is there to be made.

In my case, I bought a CBN wheel and retrofitted my old Wood-Mizer blade sharpening equipment to accommodate the wheel. The new technology was a real step forward for me and things only got better when Wood-Mizer brought out its own blade sharpening and blade setting equipment. The key to the CBN sharpening approach is that Wood-Mizer has shaped the wheel to exactly the profile of Wood-Mizer’s blade and, the wheel stays that way. The grinding wheel doesn’t have to move through the profile of the blade to do its work. It just moves up and down, sharpening the entire tooth in one movement.

Little things really do mean a lot, especially to a small business owner like I am. Pay attention to enough small things and, eventually, you might end up with something big!

Simon Petree owns Green Leaf Forest Products near Lynden, Washington. He is currently working on a book aimed at sharing the lessons he’s learned milling more than five million board feet of lumber, timbers, slabs and other products during the fifteen years he’s been in business. Visit www.greenleafforest.com for more information.