- Images

- Videos

High-throughput optimizing lumber edgers with optical board scanning technology, electro servo sizing system, automated board alignment, 29HP or 40HP electric power, up to 460 ft/min variable feed speed, 19 - 11/16" max material width, and up to 1 - 3/4" max material thickness.

High-throughput optimizing lumber edgers with optical board scanning technology, electro servo sizing system, automated board alignment, 29HP or 40HP electric power, up to 460 ft/min variable feed speed, 19 - 11/16" max material width, and up to 1 - 3/4" max material thickness.

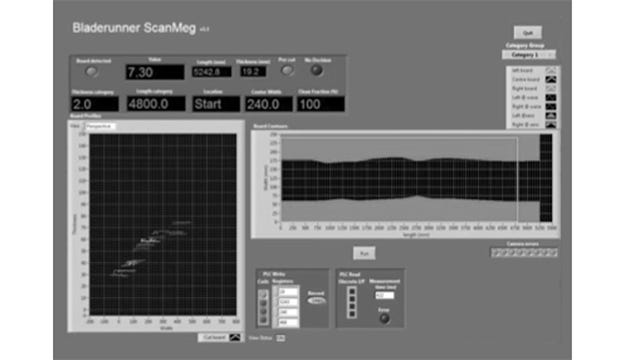

The Optimizing Edger uses optical scanning technology to achieve high precision and low waste edging of boards. The entire edging process is automated. First, each board is scanned. The profile of each board is then analyzed by a computer, which decides on the best product to maximize recovery. Decisions are based on both volume recovery and product value. After scanning, the boards pass through an alignment station and then are sawn. The EA1000/EA3000 is capable of handling up to 25 boards per minute and is the ideal machine to edge boards coming from the Resaw. Electric servo sizing system achieves any width of cut without complication. Parallel PLC / computer control systems allow the machine to be switched over to manual mode with a single button. Online support allows our technicians to dial into your machine to troubleshoot it remotely. Overall, the Optimizing Edger is a simple, robust and automated solution to your edging needs.

Waste Tailer

Outfeed automatically separates waste from finished material.

Optimization

PC vision based optimization system calculates the best cut size for each board.

Hook-stops

Hook-stops straighten boards and an operator flips boards in the wane up position.

Board Alignment

Clamps and alignment arms center the board and simultaneously top hold down rollers engage.

Blades

Two de-coupled blades can be offset; greatly adding to the value recoverable from the boards.

| Power Selections | |

|---|---|

| Power Selections | 40HP (30kW) electric60HP (45kW) electric |

| Cutting Capacities | |

| Min Width of Cut | 1.5" (40 mm) |

| Max. Material Thickness | 3" (75 mm) |

| Production Rate | 1-25 boards/min (average) |

| Blade | |

| Number of Blades | 2 |

| Blade Diameter | 17 1/2" (450 mm) |

| Blade Kerf | 0.195” (5mm) |

| Blade Adjustment Method | Electric Servo |

| Blade position | Two Centered Blades |

| Feed System & Operation | |

| Feed Speed | 500 - 820ft/min |

| Board Alignment | Automated mechanical board alignment |

| Material Hold-down | Powered Pneumatic Roller Hold-downs |

| Feed Motor | 15HP (11kW) |

| Scanning | Optical Material Scanner System |

| Operator Controls | Stationary Control Station |

| Options | In-line or transverse board scanning |