- Images

- Videos

With a simple, but effective infeed system the SVS will make light work of splitting or removing the third side from the two sided cant coming from the TVS. The SVS can also be used to take one side off a slab, which can then be passed efficiently through our horizontal resaws to recover as many side boards as possible from the slabs.

With a simple, but effective infeed system the SVS will make light work of splitting or removing the third side from the two sided cant coming from the TVS. The SVS can also be used to take one side off a slab, which can then be passed efficiently through our horizontal resaws to recover as many side boards as possible from the slabs.

The SVS Single Vertical Saw simplifies the removal of the third side of a log during processing. Placed in the line behind the TVS, the SVS prepares the cant to move on to the resaw.

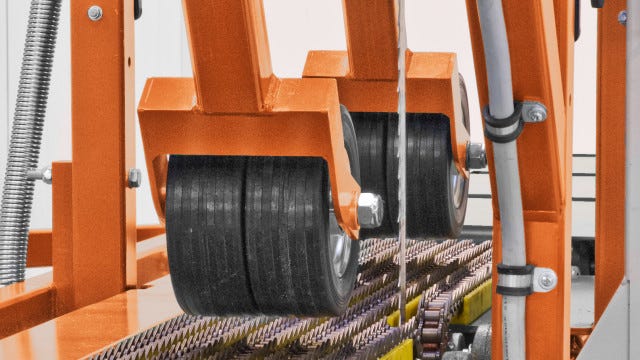

The SVS has a maximum cut width of 12". The SVS is fitted with infeed and outfeed roller tables. A steel spiked chain belt moves material through the blade up to 65 feet per minute.

With the standard laser, the operator can align the cant precisely for maximum recovery before pushing it onto the moving chain feed. Roller hold-downs make sure the log remains straight during cutting. The SVS can also be used to take one side off a slab, which can then be passed to a horizontal resaw.

The SVS shares the same head and many individual components as the TVS (Twin Vertical Saw), simplifying blade and spare parts ordering.

The SVS will make light work of splitting logs at a standard width or for removing the third side from a two sided cant coming off the TVS. Equipped with a standard laser, the operator can position the cant to gain maximum recovery or size for a resaw. The SVS is fitted with infeed and outfeed tables attached to a steel spiked chain that moves material through the blade.

Variable Feed Belt Speed

The spiked steel feed belt carries the cant through the saw at up to 20-40 fpm

15HP Electric Motor

15HP Electric Motor

Laser sight

Align cants for maximum recovery with the standard laser

Designed for Standardisation

Uses the same blade size and many of the same parts as the other machines in the SLP line, facilitating ordering spare parts.

Two Roller Hold-downs

Wide hold-down rollers keep the cant stable during cutting.

| Power Selections | |

|---|---|

| Power Selections | 10HP (7.5kW) Lincoln electric15HP (11kW) electric |

| Blade | |

| Blade Length | 184" (4,670mm) |

| Blade Wheel Diameter | 24" (600mm) |

| Blade Wheel Type | Belted Cast Steel |

| Blade Width | 1 1/4'' - 1 1/2" (32-38mm) |

| Cutting Capacities | |

| Min. Material Length | 35.4" (900 mm) |

| Max. Material Length | 12' (3.6m) |

| Max. Material Width | 16" (400mm) |

| Max. Material Thickness | 10" (250 mm) |

| Min Width of Cut | 0.4" (10mm) |

| Max Width of Cut | 11.7" (.3m) |

| Feed System & Operation | |

| Feed Motor | 1.5HP (1.1 kW) |

| Material Hold-down | Hold-down rollers |

| Alignment Laser | 1 Laser |

| Machine Dimensions & Requirements | |

| Electrical Requirements | 400V 50Hz 3Ph |

| Safety Standards | CE |

| Sawdust collection port diameter | 6" (150mm) |