- Images

High-performance, modular multi-head horizontal band resaw with one to six modular heads, steel belt conveyor, spiked feed rollers, and optional merry-go-round.

High-performance, modular multi-head horizontal band resaw with one to six modular heads, steel belt conveyor, spiked feed rollers, and optional merry-go-round.

Choose from one to eight heads on this high-end resaw with potential to produce up to seven boards at once. This machine easily integrates into existing systems and has a small footprint so you can maximize your space. The powered hold-down rollers ensure tight tolerances for the most precise requirements. An optional Merry-Go-Round (MGR) system can be added to automate the entire process of breaking down larger cants.

Performance:

- Productive - saws up to seven boards in one pass using thin-kerf technology.

- Tough - tackles any species from frozen to kiln dried.

- Accurate - Steel track conveyor keeps cuts accurate.

The HR1000 horizontal resaw is a high-performance multi-head resaw featuring a one to six head modular design, 12" wide x 12" high capacity, powerful electric motor, enhanced power transfer system, hydraulic blade tensioner, steel belt conveyor, and a variable feed rate of 0-100 ft/min. When configured with the maximum of six heads, the HR1000 resaw is capable of efficiently sawing up to six boards in a single pass. This resaw easily integrates into existing systems and has a small footprint so you can maximize your space. The powered hold-down rollers ensure tight tolerances for the most precise requirements. Options include one to six modular heads, and a merry-go-round system.

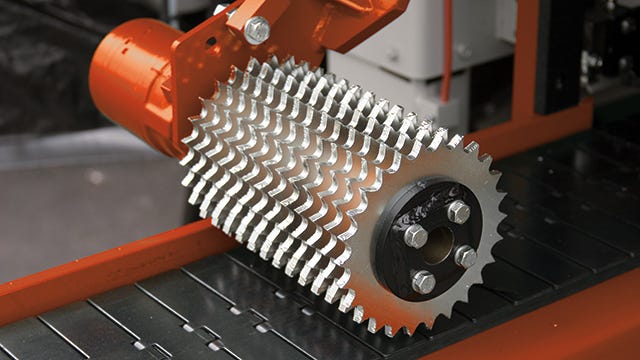

Spiked Feed Rollers

Feeds almost any species for a wide variety of applications with our hydraulic driven feed rollers.

Steel Belt Conveyor

The durable hydraulic driven steel belt provides longer life and less downtime than rubber belts.

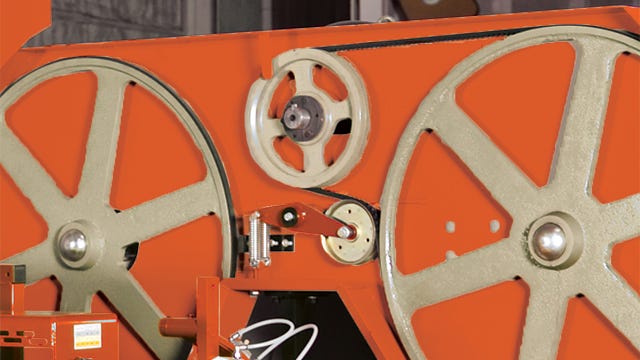

Improved Power Transfer System

Puts more power to the blade than ever before.

Blade Guides

The HR1000 comes standard with pressure roller guides.

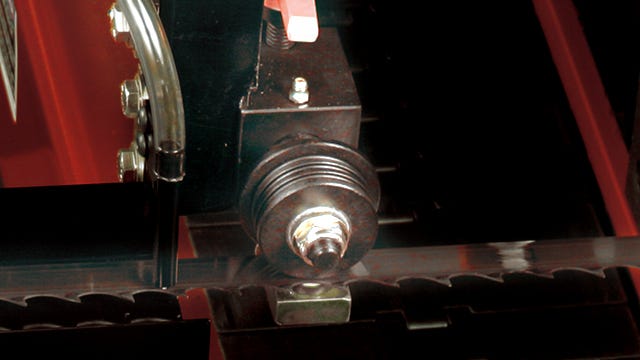

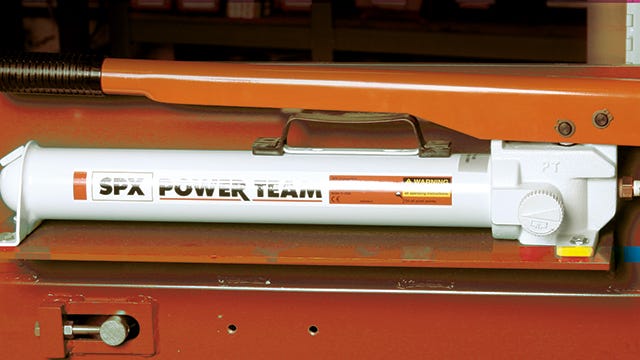

Hydraulic Blade Tensioner

Tightens blades on all heads in one place.

25HP Electric Motor

Extra horsepower for increased production.

| Power Selections | |

|---|---|

| Power Selections | 25HP electric / per head |

| Cutting Capacities | |

| Max Cant Height | 12" (305mm) |

| Max Cant Length | varies |

| Blade | |

| Blade Length | 205" (5.2m) |

| Blade Guides Style | Roller |

| Blade Lubrication System | On-location Water SupplyOptional Water Tank for each 2-head module |

| Blade Tension System | Hydraulic Blade Tensioner Assembly |

| Blade Wheel Diameter | 34" (863mm) |

| Blade Wheel Type | Belted Cast Steel |

| Blade Thickness | .035" (0.89mm).042" (1.07 mm).045" (1.14mm) |

| Blade Width | 1 1/4" (32mm)1" (25.4mm) |

| Head Features & Options | |

| Head Up/Down | Manual |

| Number of available cutting heads | 1-8 |

| Head Configuration | Horizontal |

| Feed System & Operation | |

| Feed Speed | 0-100 Ft/Min |

| Feed System | Spikey Chain Bed |

| Material Hold-down | Spiked Powered Feed Rollers with pneumatic lift |

| Machine Dimensions & Requirements | |

| Normal Power Usage | 1 head 40 Amp (15 kW motor)2 heads 75 Amp (15 kW motor)3 heads 105 Amp (15 kW motor)4 heads 140 Amp (15 kW motor)5 heads 170 Amp (15 kW motor)6 heads 200 Amp (15 kW motor) |

| Sawdust collection port diameter | 6 3/4" (162mm) |

| Shop Air Supply | 80 - 125psi @ 5cfm |