- Images

- Videos

Extra wide cut sawmill for sawing massive logs featuring a strong twin rail LX frame, extra wide sawing capacity, powered saw head controls with setworks, and powered blade guide arm.

Extra wide cut sawmill for sawing massive logs featuring a strong twin rail LX frame, extra wide sawing capacity, powered saw head controls with setworks, and powered blade guide arm.

Fast and fully-loaded with high-production features, the LT70 super hydraulic portable sawmill is engineered for sawyers that demand high-production sawing from a portable sawmill day in and day out. The LT70 is fully-loaded with engine-powered hydraulic log handling and head controls, pedestal remote control station with joystick controls, deluxe board return with outfeed table, debarker, LubeMizer blade lubrication, and more.

The LT70 super hydraulic is completely portable and ready for road travel with a standard single axle trailer and electric brakes. Six fine-adjust outriggers allow for quick set-up and precise leveling of the bed prior to sawing. The patented open side of the LT70 hydraulic sawhead allows for minimal leveling during set-up, easy off-bearing with the trapezoid shaped bed, and sawing of odd shaped logs.

Operation

Logs are loaded and turned hydraulically with loading arms and a heavy-duty bi-directional chain log turner for maximum log control. Logs are secured onto the bed by four side supports (two hydraulically controlled vertical supports for fast positioning) and a heavy-duty hydraulic log clamp. Two hydraulic roller toeboards assist with precise leveling of the log on the bed for tapered logs. Dual hydraulic pumps allow for up to twice as fast hydraulic log handling than the standard hydraulic portable sawmills. Engine-powered hydraulics efficiently control all head and bed functions through the use of high-performance horizontal and vertical energy chains. The operator can be set up at either end of the sawmill with the pedestal remote control station. Two joysticks control all head and bed functions of the sawmill including side supports, log clamp, log turner, toeboards, blade guide arm, and debarker. The joysticks can also control additional accessories such as log decks and incline conveyors. Similar to Accuset2 setworks, the control panel calculates board thickness to quickly and accurately position the sawing head automatically for the next cut while maximizing the yield per log. Once the blade is engaged with an auto clutch, the saw head advances through the log with the power feed control that includes variable speed for optimal sawing control. Once the cut is completed, the saw head is raised and reversed by the powered saw head controls and positioned for the next cut. LubeMizer blade lubrication features an adjustable electronic flow controller and pump that applies a special lubricating solution to both sides of the blade in order to melt away sap that can slow down the blade while sawing. Deluxe board return fingers and a 3' x 5' outfeed table assists with offbearing boards. A debarker helps extend blade life between sharpenings by clearing a ¼” wide path in front of the sawmill blade’s cut entry. The adjustable blade guide arm keeps the blade well supported while cutting various sized material. Blade tension is easily adjusted, and keeps the blade at the proper tension for cutting.

Features

- 36" max log diameter with 28" max width of cut and 20' 2" length of cut

- Advanced engine-powered hydraulic log handling (log loading arms, toeboards, bi-directional chain log turner, log clamp, and two vertical side supports) with dual hydraulic pumps for twice as fast hydraulic functions

- Engine-powered saw head up/down & forward/reverse for fast head positioning

- Pedestal control station with fully-proportional joystick controls allows the operator to be positioned anywhere around the mill to control all hydraulic head and bed functions

- Material board dragback with 3' x 5' outfeed table for easy offbearing

- Debarker removes dirt and bark from the blade path for longer blade life

- LubeMizer blade lubrication system for maximum blade performance

- Standard trailer with patented cantilever design, trapezoid shaped bed, and fine-adjust outriggers for precise bed leveling

- Built in the USA

Popular Options

- Wide sawmill head increases max width of cut to 34"

- Laser sight pinpoints the precise location where the blade will enter the log for reducing inefficient cuts and increasing yield

- 6' bed extension can be added to saw longer lengths (26' 2" max length of cut)

The LT70 super hydraulic portable sawmill comes fully assembled with one Wood-Mizer sawmill blade. Free one-on-one sawmill training by an experienced service representative is included during your Wood-Mizer location pick up or home delivery. With a 30-day money back guarantee, 2-year sawmill warranty, and 5-year chassis warranty, the LT70 super hydraulic is backed by the same level of service, quality and safety features shared by the entire family of Wood-Mizer wood processing equipment.

Saw extra-wide slabs and boards up to 54-1/2" with the LX250 Wide Slab Sawmill using powered saw head controls (forward/reverse & up/down) and SimpleSet Setworks! Designed for sawyers and woodworkers that need to saw massive slabs and boards, the LX250 joins the Wood-Mizer LX Series of sawmills that are engineered to saw wider and deeper than other sawmills in their class.

Operation

Loaded and turned with support equipment, logs are secured on the convenient raised bed cross sections by three adjustable steel side supports and two adjustable log clamps. With powered up/down, the saw head height is precisely positioned for each cut. SimpleSet setworks saves two pre-set board thicknesses to quickly and accurately control blade height while referencing from the previous cut. Once the powered blade guide arm is adjusted for the cut, the blade is engaged and saws through the log by the powered forward/reverse controls using a dual power feed chain system. Turned on and off with a manual valve, the gravity fed lubrication is applied directly to the blade to keep it clean and free of pitch and sawdust build-up. Once the cut is completed, the saw head is raised and reversed by the powered saw head controls and positioned for the next cut.

Features

- 55” max log diameter with 54 ½” max width of cut

- 13' length of cut or 18' max length of cut with optional 5' bed extension

- Rigid LX Frame sawhead tower with heavy-duty twin rail bed construction

- Powered saw head up/down & forward/reverse with dual power feed system

- SimpleSet Setworks allows two pre-set board thicknesses to quickly and accurately control blade height while referencing from the previous cut

- 8 heavy-duty mounting feet along bed rails with 3 extra middle supports

- 38HP EFI Kohler Gas Engine or 15HP 3-phase electric motor

- Built in the USA

Popular Options

- 5' Bed Extension

Durable Steel Bed

To withstand continuous sawing and the weight requirement of larger logs.

55" Log Diameter Capacity

With 54 ½” max width of cut for sawing wide, live-edge slabs and boards.

LX Frame Tower

Holds the control panel, engine, and the sawmill head in a rigid, stable structure that travels on twin parallel hardened steel rods on the bed.

Pallet Weight / Dimensions

3,420 lbs (1,551 kg) / 96" x 118" x 78" (3m x 2.4m x 2m)

11 Mounting Feet

8 heavy-duty mounting feet along bed rails with 3 extra middle supports.

2 Parallel Hardened Steel Rails

Provide a smooth and stable dual track for the saw head to travel on.

2 Adjustable Log Clamps

For additional stability when clamping a log, cant, or a final board.

Powered Saw Head Controls

Including forward/reverse and up/down for ease of operation and increased production.

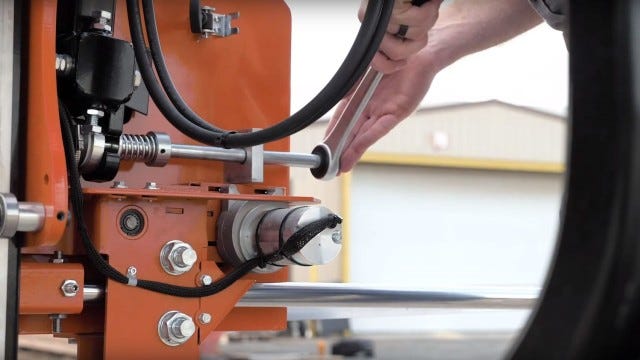

Powered Blade Guide Arm

Adjustment is activated from the control console for operator convenience and precision.

3 Adjustable Steel Side Supports

Provide improved durability and stability when loading, turning, and sawing heavy logs.

Hydraulic Blade Tensioning

Keeps blade properly tensioned for longer blade life and enhanced sawing performance.

Raised Cross Sections

For easy loading of logs with a forklift or tractor, without having to drop or roll logs onto the saw bed.

| Power | |

|---|---|

| Power Selections | 15HP (11kW) electric38HP (28.3kW) Kohler gas |

| Cutting Capacity | |

| Max Width of Cut | 54 1/2" (1.38m) |

| Max. Log Diameter | 55" (1.4m) |

| Max Log Length | 13' 5" (4.1m) |

| Max Log Length (with extensions) | N/A |

| Blade | |

| Blade Lubrication System | Manual valve blade lubrication |

| Blade Tension System | Hydraulic Tension System |

| Blade Wheels | |

| Blade Wheel Diameter | 19" (483mm) |

| Blade Wheel Type | Belted Cast Steel |

| Head Features and Options | |

| Operator Location | Walk Along Electric Feed |

| Setworks | SimpleSet Setworks |

| Head Forward/Reverse | Power Feed |

| Head Up/Down | Electric with Setworks |

| Blade Engagement | On/Off Button (Electric Versions) |

| Blade Guide Arm | Powered Adjustment |

| Debarker | N/A |

| Bed Features and Options | |

| Side Supports | 3 Adjustable Side Supports |

| Log Leveling | N/A |

| Log Turning | Manual |

| Log Loading | Manual |

| Trailer Package | N/A |

| Log Clamping | 2 Adjustable Log Clamps |

| Additional Bed Options | Optional 5' (1.52m) Bed Extension |

| Machine Dimensions and Requirements | |

| Bed Construction | Twin Rail |

| Frame Construction | xFRAME |

| Mobility | Mobile |