By Jesse Pryor, Missionary, Papua New Guinea

February 26, 2020

It’s around 6 am and the bug’s chirping and the bat wing flapping give way to the singing of birds in the dense foliage above us. When an adult-sized bat flaps its 4-6’ wingspan in the middle of the night, you hear it. Trust me on that!

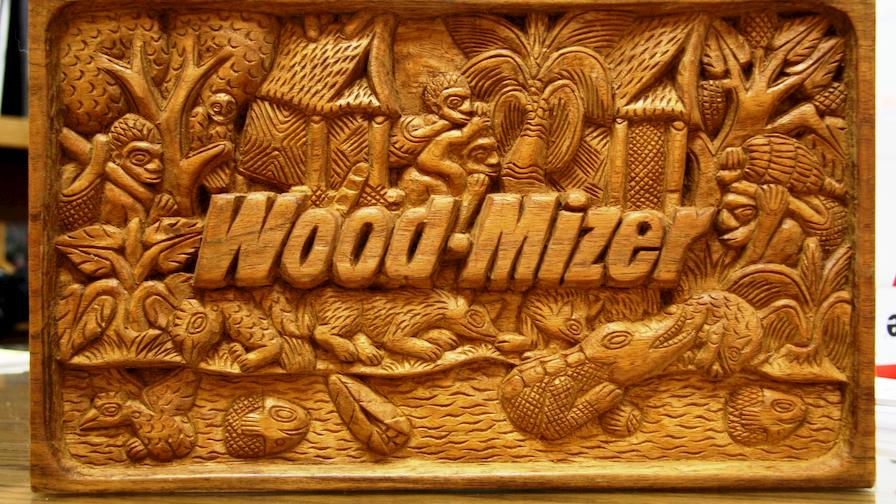

Yesterday had been a long day for the six members of the sawmill crew. We had loaded the various pieces of the Wood-Mizer LT15 Sawmill into our 50’ dugout canoe. The 40hp outboard motor had run well with no mechanical issues. However, the trip had been eventful because of a tree that was hanging low across one particular spot in the river. The mast of the sawmill just would not make it under the low-hanging limb. Fortunately we had a chain hoist and a chainsaw that allowed us to cut and pull the tree out of the way.

So after five hours on the river, we arrived at the pre-determined location of this milling trip’s timber stand. The mill is carried in sections back to the site, after the chainsaw operators had felled two of the trees. We have found that felling is crucial before you set up the mill in the jungle. No one wants to carry the mill once it’s together, especially if it’s in the way of an oncoming tree!

The next morning, two of the crew begin boiling water and cooking in the fire pit to start the morning breakfast meal. It was good that the log owners built the hut the day before while we were felling the trees and carrying the LT15 sawmill to the site, otherwise we would not have had someplace to sleep off of the ground during the night. Poisonous snakes make poor bunkmates. They live on the ground, so all the huts are built on stilts. It just makes sense.

The rest of us begin assembling the sawmill. We selected the site last night and spent the last hours of the day using axes and machetes to clear the site. This makes setup a lot easier. Experience has also taught us to carry four boards with us to put the feet of the stands on. When you work in the swamp and rainforest, the "feet" sometimes find a soft spot. We have four particular boards that we lay down for the tracks to sit on. These boards have been augured out to the exact spacing and diameter of the "feet." We mill hardwoods, namely ironwood or Kwila (to the locals), so the better anchored the mill is the better. We drive two stakes at the very ends of the track to keep it from moving when we begin to roll the logs on.

The LT15 is now level and ready to go. Check the oil in the engine! We are in the middle of nowhere, literally! So any damage to equipment, especially from negligence, is very bad. Any damage to that engine, and the whole trip will have to be abandoned. We normally let it idle for five minutes while we roll the log on the mill. The agreement we always have with the landowners/tree owners is always a one-to-one exchange. One tree milled for us to mill for our projects, and one tree milled for their use allows for both sides to benefit equally. Part of the agreement is that they are there to help with the moving of the logs (no forklifts here) and the positioning of the logs on the mill. They also help with timber stacking.

While the mill is warming up after the log is clamped and ready to go, it’s time to talk safety. We lay out the safety rules of working around the mill. Where and when you should approach the mill are just a couple of the topics we discuss. OK, the engine has idled way past five minutes now, but that’s alright. Someone had to take the water container back to the river to fill it so the blade would be washed and cooled properly. We had checked the blade before we cut the first piece, but after the first time through it’s time to make sure that everything is in order. We’re good to go!

The operator starts to mill up the first section of log. It’s the job of the operator and the "water boy" to mill the log, and give the directions to the local guys working with the sawmill crew. The rest of us go back to the hut for a little meal. We’re going to be working all day in the heat. It’s important to stay hydrated and fed. The guys in the crew have specific roles. Three of the guys have been trained to operate the sawmill. They are the only ones that can accurately read a tape measure, consistently. Two other guys operate the chainsaw.

The calm of the jungle for a few short weeks is replaced by the whine of a chainsaw, the noise of a diesel engine, and the yells of the men as they shout directions at each other. There is a brief lull though. One of the bearings in the blade guide has gone bad. We take about 30 minutes to replace it. Fortunately for us we always have an ample supply of what I call consumable parts on standby! Wherever the LT15 goes, so does the large box of spare parts. No local hardware, or Wood-Mizer outlet nearby here! We’re off and running again! A few hours later the pile of finished lumber has steadily grown larger. Everyone is grinning from ear to ear, while the sawmill just keeps on cutting away. Scraps are claimed for someone to whittle out an oar for paddling on the river. No one goes home empty handed, that’s for sure. Another lull in the action, a 15 minute rain shower passes. We are in the jungle and they don’t call it the rainforest for nothing!

Days start early, around 6am, because that is when the first light starts to show. We keep busy until 6pm, when the sun starts to set. That leaves us with about 30 minutes to bathe in the river, and prepare supper. No indoor plumbing here, and swimming after dark might lead to an encounter with a crocodile! The day is beginning to wind down. The spring in our step just isn’t quite the same at the end of the day when it has been 90F with very high humidity. Heat index says it felt like 114F. I would say that an estimate like that is not to far off judging by the way I feel.

We light the kerosene lamp before we head off to the river. We won’t get back from our "bath" till after dark. So having a light helps with preparation of supper, and finding your way back. Things are quiet again. It’s a nice "cool" evening. The bugs start the chirping again. The guys laugh and joke about the day’s work. It always amazes me how exhausted people can be so happy. We know that we are a few steps closer to finishing up, and look forward to the day we wrap it up here and head back to our home in Samban, a small village in the East Sepik Province of Papua New Guinea. It’s good to sit and rest after being on our feet and working all day.

Jungle Milling Tips

1. Keep the chainsaw handy when transporting your sawmill upriver.

2. Build the hut before you start sawing, and make sure your sleeping bunks are off the ground.

3. Stay hydrated and fed.

4. Bring spare parts for everything.

About the Author

Born and raised in the jungles of Papua New Guinea, Jesse Pryor returned as a missionary with his wife Karie and three children to continue the work begun by Jesse’s parents John and Bonita Pryor. They are working within the church to strengthen discipleship and Sunday School programs. With the help of the locals and the sawmill crew, Jesse has put his experience in the construction field to good use, and they have completed churches, schools, and medical facilities in the remote jungle.